任務:歸零

資源短缺,環境污染和氣候變化是我們今天面臨的最大挑戰。奧迪通過製造可持續產品、開發創新的驅動技術以及在生產階段就作源頭減廢,來應對這些挑戰。這意味著要謹慎使用能源和水等資源,並避免碳排放、溶劑和廢物。

奧迪如何實現碳中和生產?

車輛製造會在各個階段產生碳排放,包括在工廠提供電力、供暖或運輸。

2014 年,奧迪是第一家根據國際認可的標準確定公司碳足跡的高端汽車製造商。這標誌著奧迪向溫室氣體排放透明化邁出的關鍵一步。如今,可以對這些排放物進行更詳細的分析,並有效減少排放量。

布魯塞爾就是一個例子:經獨立專家認證,該廠的生產完全是碳中和的,令這奧迪廠房既是先鋒,又是榜樣。在這裡製造第一部純電動批量生產的汽車,即 Audi e-tron,也是合乎邏輯的。這不僅是確保公司自己未來的努力,而且是在實現可持續發展戰略目標中發揮其作用的一項努力成果。

綠色電力

早在 2012 年,奧迪在布魯塞爾就開始購買綠色電力,並防止每年排放多達 17,000 公噸的二

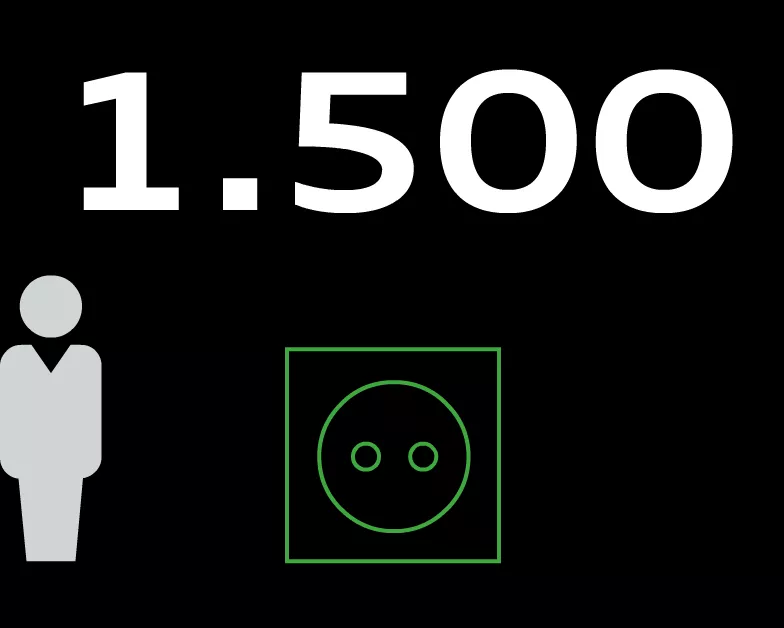

氧化碳。 在 2013 年,安裝了該地區最大的光伏系統。在 2017 年,廠房設施進行了擴展。現在,它的面積為 89,000 平方米,大約是 12.5 個足球場的大小,它產生的綠色電力足以為 1,500 多名四人家庭提供一年的電力。同時,由於購買了沼氣證書,此廠房的供熱系統實現了碳中和。燃料、取暖油或焚燒溶劑產生的所有其他排放均通過所謂的碳信用項目來抵消。

除了減少碳排放外,還採取了其他措施來改善廠房的環境足跡。其他項目通過節約用水和能源、或減少在空氣和水中的污染物排放來保護環境。

所有過程都基於效率。這包括避免使用對環境有害的物料,並充分利用資源。尖端技術被用來實現這一目標。

布魯塞爾的環境保護

概覽顯示了布魯塞爾廠房的環境保護有多麼多樣化和廣泛,並概述了生產設施中正在進行的項目。

奧迪集團生產基地

以下概述顯示了一些例子,它們有助於確保公司達到其生態目標。